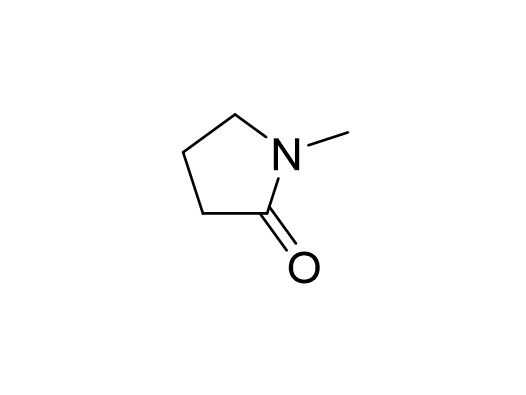

N-Methyl-Pyrrolidone

Molecular Formula:C5H9NO

CAS:872-50-4

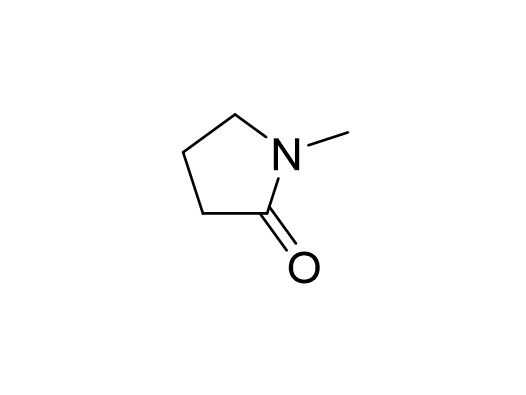

Molecular Formula:C5H9NO

CAS:872-50-4

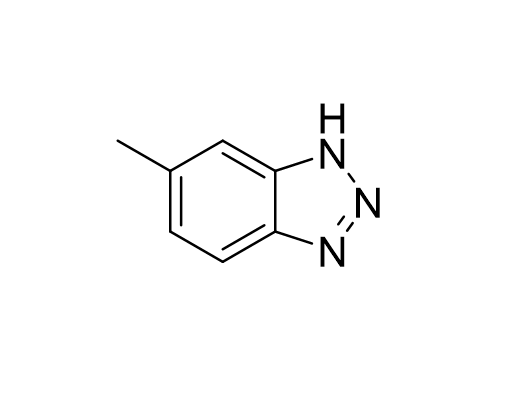

Molecular Formula:C7H7N3

CAS:136-85-6(49636-02-4)

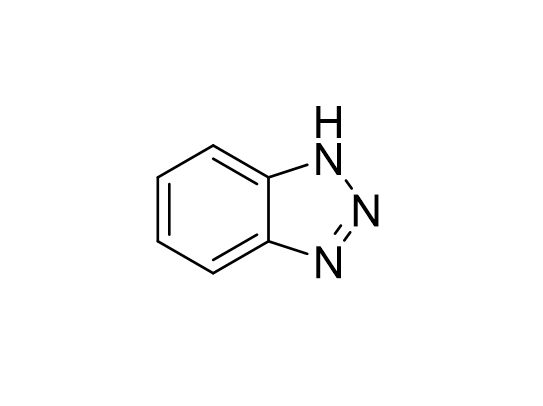

Molecular Formula:C6H5N3

CAS:95-14-7 (27556-51-0)

more product of cleaning solution raw materials

Designed for semiconductor and optoelectronic cleaning, effectively removing micron- and nano-level particles and organic residues.

Fully compliant with ROHS, REACH, halogen-free, and fluorine-free standards, supporting green manufacturing.

Safe for metals, glass, and plastics with no corrosion, adaptable to various process requirements.

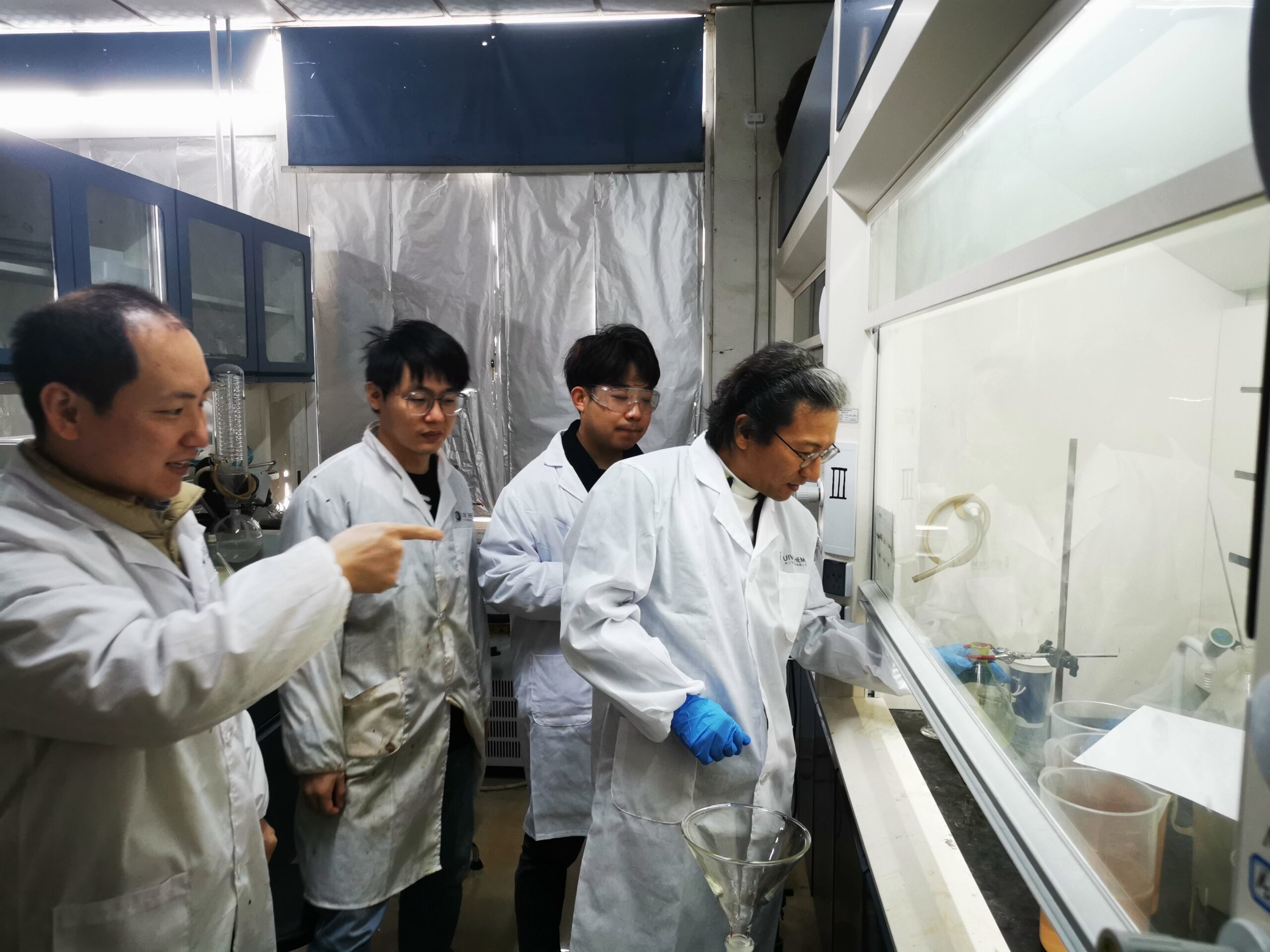

1200 square meters large r&d centers and 2400 square meters 1k grade clean workshop

At UIV CHEM, you're not just choosing a material supplier—you're choosing a long-term partner in innovation and precision. With a vertically integrated supply chain and strong R&D capabilities, we deliver cutting-edge chemical solutions from lab to large-scale production.

Core team with 15+ years of experience, backed by postdoctoral and academician-level expertise.

Full Industry Chain Coverage: From raw materials to end products across photoresists, silicone, resins, polyimide, and cleaning solutions.

Lab-scale samples to ton-level production—tailored to your process needs.

Discover what our clients have to say

Partnering with UIV CHEM is straightforward and built on trust and integrity

Requirement confirmation and form submission.

Price negotiation and order confirmation.

Factory production and delivery.

After being cleaned and self-inspected by the supplier, the PE drums are delivered to the factory. Upon arrival, IPQC and operators inspect the interior of each drum, requiring that it is visually free of particles, discoloration, oil stains, or other contaminants.

The drum is made of polyethylene (PE) material, and various packaging options are available according to customer requirements, including tank trucks, IBC totes, 200KG drums, and 25KG drums.

≤200 ppm for drum packaging and ≤150 ppm for tank truck packaging. Filtration is performed using appropriate filter elements according to customer requirements, and particle levels are controlled to meet customer specifications.

Each individual metal ion (e.g., Na, K, Mg, Ca, Cr, Mn, Fe, Co, Cd, Ni, Zn, Cu, Al) ≤10 ppb

Most development cycles range from 2 to 6 weeks, depending on the formulation complexity and testing requirements.